PC Based Systems VS Smart Cameras

June 11, 2021

It is no longer new to anyone that computer vision systems are powerful tools already used in factories to ensure the quality of their products.

The market is increasingly and better prepared, responding with a variety of solutions increasingly reliable, comprehensive, fast, and often economical to market needs.

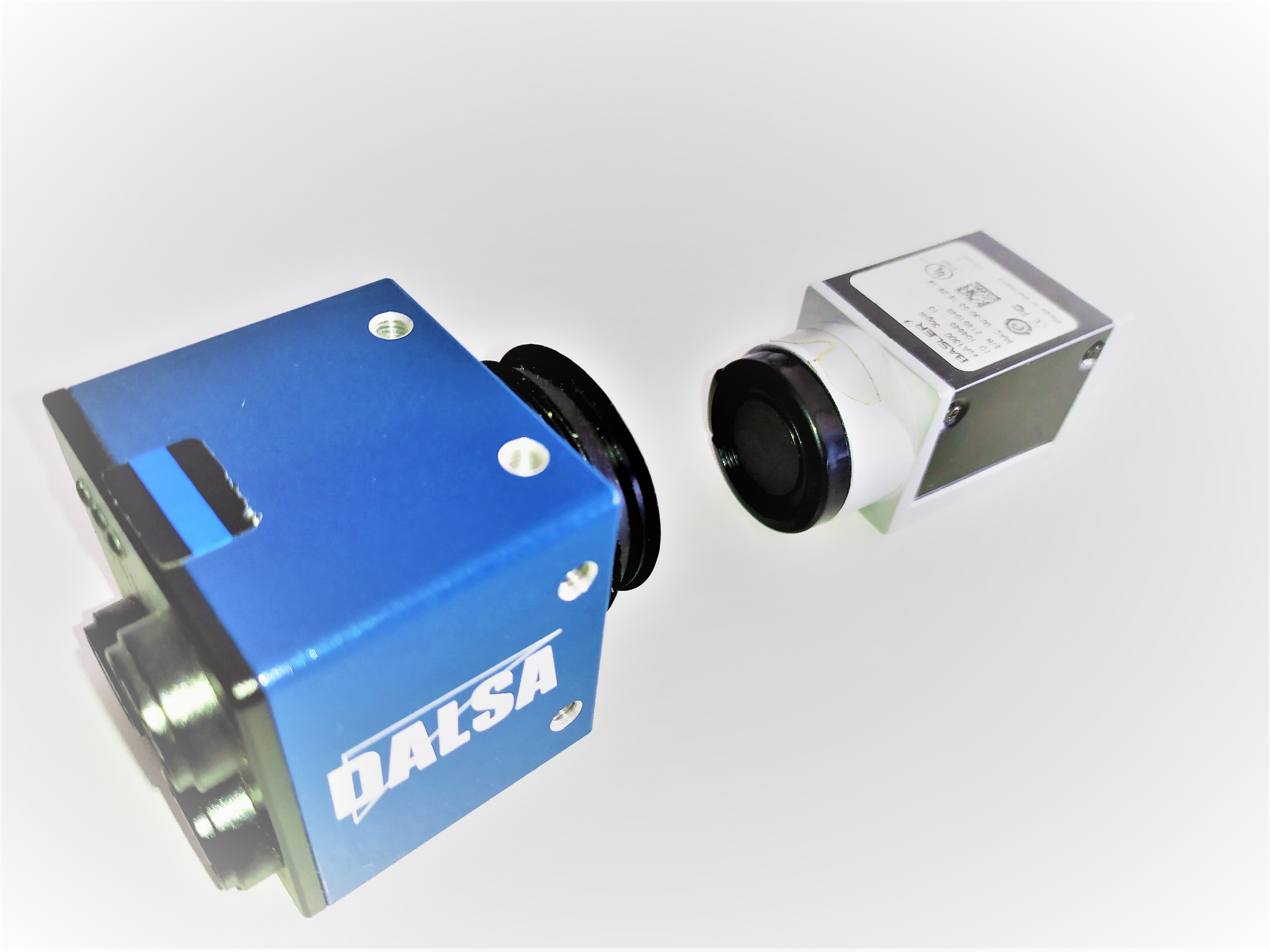

Given this panoply of strategic decisions regarding the choice of the platform of the predominant technology in the production lines, there are often some doubts. One of the most common is between smart cameras and more closed PC based systems.

Of course, this doubt only takes place when the two technologies are possible solutions to the same problem.

First, to facilitate our decision, we will put some limits on these two entrenched sides. When I refer to smart cameras, I mean systems that in addition to the camera also have a main frame that is in most cases easily configurable by the end user without the need for much training, with some generic image processing tools and sometimes with built-in lighting.

On the other hand, when I refer to PC based systems, to have a fair comparison, I refer to systems made in a programming language, with the use of image processing libraries.

Not forgetting that in the middle there are also other options, which are systems that despite being PC based, work on a main frame easily configurable by the end user with little training.

All this without forgetting that there are other derivations that for one reason or another cannot be weighted for standards of a production line:

- Vision sensors - They can detect a particular color or do the recognition in a certain way, these sensors, although potentially useful in certain functions, could never be seen as the standard given their meager capabilities.

- Embedded vision systems - These are devices that have camera and processing capacity. They do not have a predefined main frame, but the programmer can use the external libraries to do image processing. In this case, although they are often ideal for the development of a product with some massification, in most cases they do not have the flexibility enough to constitute a standard.

- Systems with special requirements – They are systems that, at your request, leave no choice but the use of specific libraries, such as MIG welding analysis, defect in natural products.

Therefore, we will analyze point by point with the aim of reaching some conclusions.

The starting price is undoubtedly an important differentiating factor when we choose something, but can we even say that one raw material is more expensive than the other? In my opinion the answer to this question is NO. When we talk about smart cameras with some capacity, we can hardly find anything below the pair of thousands of euros, a cost that can be multiplied by three or four times if we are more demanding in the choice. With this value we can buy the raw material for a PC based system with equivalent capacity.

The space occupied is undoubtedly an important factor for the choice, the shop floor is sometimes the most precious resources in an industry. In this specific aspect smart cameras take a great advantage because there is no need to be reserved space for the PC and other conditionings.

Ease of use and adjacent features are another important factor. Here there is no doubt that a PC based system leads to the best, where it is possible to do user management, variety management, the information can appear on the monitor in the most intuitive way that the programmer can imagine, track all the data in databases and make it available in the most useful way possible.

The maintenance costs also make me lean over to the PC based solution, because the smart cameras, in case of malfunction, the complete device that must go to repair and the costs are often more than half the value again.

Unlike PC based systems, smart cameras typically allow the product engineer or maintenance engineer to make changes to the main frame configurations, however, with good specification and planning, the PC based system can also maintain the necessary configurable settings and in a more stable way, as they only allow changing what is likely to have to be changed over time. Moreover, in my opinion, the core business of factories is to manufacture, will never spend resources on vision systems and other machines of their production lines.

After these years of industry, based on these points detailed here, I believe that in most cases, PC based systems are the best options.

We have a new image!

May 10, 2021

This week the new MCM website was online, which I invite you to visit.

With the new website, the new logo, the new trade name, and the new domain that includes e-mails were also made public.

The new website is at www.mcmsystems.pt, which also became the domain of e-mails.

These changes are part of a broader change in the company's communication policy, as well as a greater emphasis on digital marketing.

#ComputerVision #MachineVision #ArtificialIntelligence #InteligentVisionSystems #Machinery #MachineLearning

We moved facilities!